17.4 Fermenter engineering

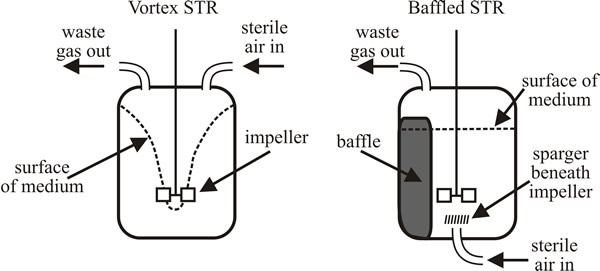

In stirred tank reactors the oxygen transfer rate is affected by the type of stirring (Fig. 5). In a vortex STR rapid rotation of the impeller causes a vortex in the fluid that draws air bubbles into the liquid, which are then dispersed by the impeller. Vortex STRs are very rarely used now. It is important to appreciate the contribution made by biochemical engineers to fermentation microbiology in terms of fermenter design and operation. Aeration may be improved further by having the air supply entering the culture just below the impeller so the incoming air stream is immediately broken up into very small bubbles (a process known as sparging). In the baffled STR, a baffle on the inner wall of the tank prevents vortex formation but it increases turbulence in the fluid and so increases aeration (Fig. 5). Baffles can also be used in conical flasks for small-scale cultures. Sometimes 4 baffles are added to conical flasks by a glass blower indenting the sides of the flask. Flexible metal coils can also be added to conical flasks. Both strategies increase turbulence, and hence aeration.

|

|---|

| Fig. 5. Types of Stirred Tank Reactors (STRs). Left: vortex STR in which the air is entrained by the vortex and dispersed in the liquid by the impeller. The sketch on the right shows a baffled STR in which a baffle on the inner wall of the tank prevents vortex formation and increases turbulence in the fluid, and increases aeration that way. |

Culture viscosity is low in the region of the impeller and this increases the rate of oxygen transfer from the gaseous to liquid phase, so this is a well aerated region in the fermenter. In regions of the fermenter near the walls of the vessel, the culture may suffer poor aeration and be stagnant.

|

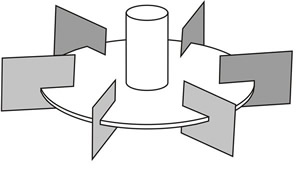

Fig. 6. Engineering sketch of an efficient fermenter impeller. This pattern is known as a Rushton disk turbine, designed by Rushton, Costich, & Everett (1950). The 4- and 6-bladed (shown here) versions of the impeller are most common, but it may have 3, 4, 5, 6, 8 or 12 blades depending on the application. Rotation of this radial impeller forces the fluid to flow radially at right angles away from the impeller shaft (in contrast to ‘marine screw’ style axial impellers, which force the fluid to flow along the axis of the shaft). |

|---|

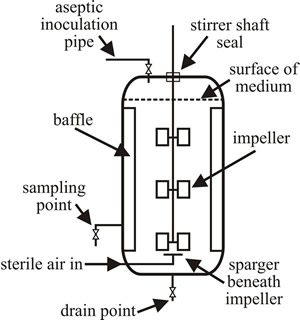

The most efficient type of impeller is a vaned disc, most commonly with 6 or 8 vertical vanes (Fig. 6). Optimum diameter is about 40% of the vessel diameter and optimum vane height is about 17% of the diameter of the impeller. Within the fermenter, the impeller should be one third to one half of vessel diameter above the base of vessel and the larger industrial units will have two or three impellers on the same shaft (Fig. 7). In terms of oxygen transfer rate, the most effective position for the outlet of the sparging air is immediately below the impeller. In practice, cultures are usually sparged at a rate of one culture-volume of air per minute (Fig. 8).

|

Fig. 7. Engineering sketch showing, in sectional view, a typical large (100 m3) industrial STR fermenter that would be constructed in stainless steel. |

|---|

The degree of agitation in the STR has a profound effect on KLa because, by forming small bubbles:

- agitation increases the surface area for oxygen transfer, so the rate of stirring affects oxygen transfer rate (Fig. 8), to be specific, laboratory-scale cultures in 2-litre fermenters are usually stirred at a rate of 1000 to 1200 rpm;

- delays escape of bubbles from the liquid (giving a longer period for gas exchange);

- prevents coalescence of bubbles;

- turbulence decreases the thickness of the stationary liquid film at the gas/liquid interface.

- concentration of biomass also affects oxygen transfer rate because of its effect on the rheology of the culture (Fig. 8). This depends on morphology; filamentous microorganisms form more viscous cultures than unicellular microorganisms.

It is good practice to monitor the oxygen content of the medium during cultivation, so that stirring and sparging can be adjusted if necessary. This can be done with oxygen electrodes.

|

|---|

| Fig. 8. Influence of air sparging, stirrer rate and biomass on oxygen transfer rates in stirred tank reactors. A, Effect of air sparging on oxygen transfer rate. B, Effect of stirrer rate on oxygen transfer rate in a vortex STR. C. Effect of biomass (concentration of Penicillium chrysogenum) on KLa in a stirred tank reactor. |

An important function of the impeller is to diminish the size of air bubbles, but there are limits to this because the formation of foams must be avoided. A foam is a stable mass of frothy bubbles formed in a matrix of the culture fluid that can accumulate on the surface of the medium. The foam is stabilised by proteins, peptides and other materials that leak into the medium from the biomass. Bubbles trapped in the foam become depleted of oxygen and impede gas exchange because they are isolated from the air flow. Addition of antifoam reduces foaming; antifoams are chemical additives that have affinity to the gas-liquid surface where it destabilises the foam by promoting coalescence of the smallest bubbles into larger ones that rupture and release their gas content into the air flow. Examples of commonly used antifoams include: polyalkylenglycols, alkoxylated fatty acid esters, polypropylene glycol (PPG), siloxane polymers, mineral oils and silicates used at concentrations up to 1% of the total volume.

In a stirred tank reactor heat is generated by the stirring power needed to aerate the culture and this is additional to the heat generated by the chemical activities of the biomass. To avoid heat build-up a cooling system is required. The most usual design is a water jacket made up of water circulating through tubes either on the outside or within the fermenter.

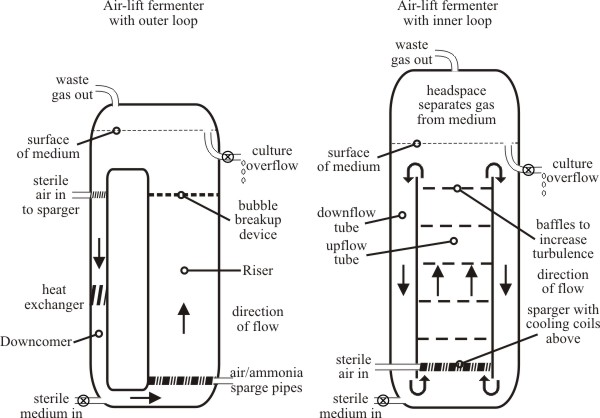

Air-lift fermenters (Fig. 9) avoid the heat generated from stirrers. They work because of the density difference between aerated and non-aerated medium (strictly speaking, since the medium is a fluid it’s a specific gravity difference). The specific gravity of air-depleted culture medium is relatively higher than the specific gravity of air-enriched (that is, newly-sparged) medium, so the latter tends to move upwards and generates the required agitation of the fermenter contents. Furthermore, elevated hydrostatic pressure in the sparging zone increases oxygen transfer into the medium by increasing its solution rate.

|

|---|

| Fig. 9. Sketch diagrams of typical air-lift fermenters. Left, a laboratory scale (glass) air-lift fermenter with outer loop, in which the diameter of the downcomer should be as narrow as possible to minimise hold-up time. Right, an industrial air-lift fermenter with inner loop (typical of very large fermenters used to produce single cell protein for animal feed). The rigs can be operated as continuous flow systems when culture overflow and sterile medium input lines are both open; or in batch mode when both of these are closed after the vessel has been charged with medium and inoculated. |

Updated July, 2019